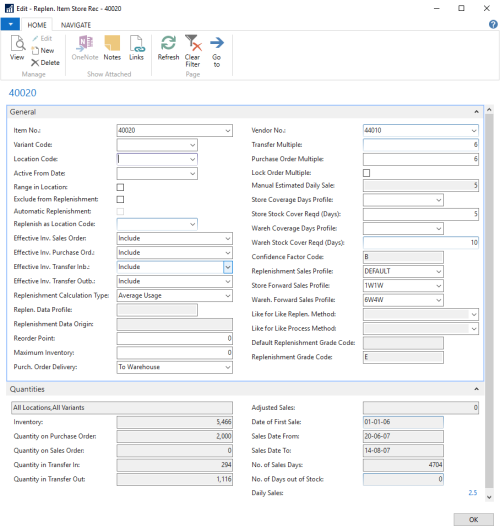

In the Replenishment Item Store Record you can enter replenishment parameters for a certain item (and variant) and location. The information stored in this record overwrites the information on the Retail Item card.

The Item Store Record contains the same Replenishment Data fields as the Item record. It is found on the Retail Item Card: click the Replenishment Control Data action and then Replenishment Item Store.

The record only shows relevant fields according to the value of the Replenishment Calculation Type field.

On the General FastTab you can fill in the Item No., the Variant Code for items with variants, the Location Code and the Active From Date. The Item No. is automatically filled in if you open the Replenishment Item Store Rec. form from the Retail Item card. You can only enter a valid variant code in the Variant Code field. Use the Lookup functionality to select the Location Code.

You can have new parameters take effect on a certain date, if you fill in the Active From Date field.

The Quantities FastTab contains various information fields such as the Inventory, Quantity on Purchase Order, Quantity on Sales Order, Quantity in Transfer In, Quantity in Transfer Out and the Adjusted Sales quantity fields.

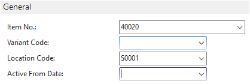

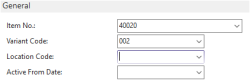

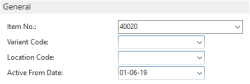

The key for the Item Store record is Item No. + Variant Code + Location Code + Active From Date where Item No. must be filled in and one of the other fields also. This gives you the chance to create specific Replenishment Data for a specific store or new data that will take effect in the future.

Examples:

This record would be valid for all Variants and Store / Location S0001.

This record would be valid for all Stores / Locations and the Variant 002.

This record would be valid for all Stores / Locations and all Variants, but not until June 1, 2019.

This way it is possible to plan replenishment when the item is created and all the way through its lifecycle.

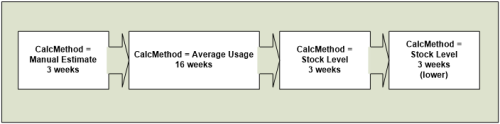

Note: The field Active From Date can be used to create a lifecycle for an Item by assigning different Calculation Methods and Replenishment parameters during time.

At the beginning of the lifetime, the Item could be calculated with the method Manual Estimate and the purchaser gives his or her estimate for daily sales.

After a couple of weeks, when you have collected enough sales history, the Item could be calculated using the method Average Usage, using the sales history to predict the future demand.

At the end of the lifecycle, when you want to get the Item out of the stores, the Item could be calculated with the method Stock Levels, where you provide a maximum quantity which could be reduced stepwise.

The setup can be made in advance by using different Active From Date values.

Automatic Replenishment will change the calculation methods and parameters automatically according to the different dates.

To add multiple Replen. Item Store Recs

- Use the Add Locations/Variants action, in the Process group, to add multiple locations and variants simultaneously. See How to: Add Locations or Variants for more details.